Unlocking the Potential of Lithium Batteries with New Electrolyte Solutions

Imagine a world where your smartphone battery lasts for days, electric cars charge faster and drive longer, and renewable energy storage is more efficient. This isn’t a distant dream but a possibility being unlocked by groundbreaking research in lithium metal batteries. The key? A novel electrolyte solution that promises to revolutionize how these batteries operate.

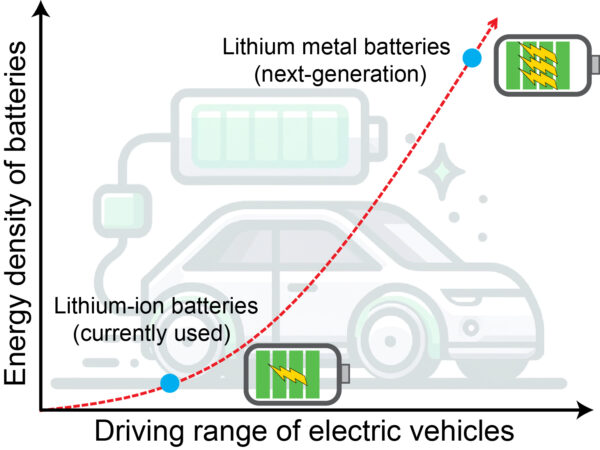

Rechargeable lithium batteries are a cornerstone of modern portable electronics, offering a reliable power source for a wide range of devices. At their core, these batteries consist of three key components: an anode, a cathode, and an electrolyte that enables the flow of lithium ions between the anode and cathode during charging (that converts chemical energy into the desirable electrical energy) and discharging (electrical to chemical energy) cycles. The unique chemistry of these batteries allows them to be recharged repeatedly, making them both efficient and environmentally friendly compared to single-use alternatives. This ability to efficiently store and release electrical energy is what has propelled lithium batteries to the forefront of energy storage technology. The specific variant of lithium batteries that ubiquitously powers all electronic gadgets and electric vehicles (EVs) is called a lithium-ion battery. A lithium-ion battery consists of graphite (a form of carbon, the other popular form of carbon you may know as diamond!) as anode and a ceramic solid (mostly contains metal, lithium, and oxygen) and the electrolyte consists of salts (not the one you use in your soup!) dissolved in organic liquids. Their widespread adoption is due to their high energy density (energy stored in a battery per weight) and long life. However, as we push the boundaries of technology and seek more sustainable and efficient energy solutions, the limitations of lithium-ion batteries become apparent. For example, the driving range of EVs is currently limited by the amount of lithium that can be stored in graphite anode in the lithium-ion batteries. This is where the next generation of batteries, such as lithium metal batteries (LMBs), comes into the picture. LMBs promise even higher energy densities, potentially doubling that of standard lithium-ion batteries as they use lithium metal instead of graphite as the anode, and offer faster charging times. This makes them particularly attractive for applications requiring more intensive energy storage, like long-range EVs and more efficient integration with renewable energy sources.

However, their widespread use of LMBs is hampered by two major challenges. The first major challenge lies in the selection of electrolyte, which is crucial for enabling the flow of lithium ions and hence in the generation of electrical energy. The traditional electrolytes used in lithium ion batteries show increased reactivity towards lithium metal anode. They often fail to support the efficient movement of lithium ions and contribute to the rapid degradation of the lithium electrode. This incompatibility significantly hinders the battery’s performance and lifespan.

The second challenge is the uneven deposition of lithium during the charging process (when lithium ions get transported to the anode they get deposited as lithium metal). This unevenness often results in the formation of lithium ‘dendrites,’ needle-like structures that can grow through the electrolyte layer. These dendrites not only reduce the efficiency and lifespan of the battery but also pose significant safety risks. They can create short circuits within the battery, leading to potential failures or, in extreme cases, safety hazards.

The exciting news? We have developed a new type of electrolyte solvent, the fluorinated borate esters, which dramatically enhances the performance and safety of lithium metal batteries, in a recent work published in the Journal of Materials Chemistry A.

Figure: Development of next-generation batteries such as lithium metal batteries can significantly increase the driving range of current electric vehicles by manyfold. The main bottleneck to the realization of such next-generation batteries is the lack of suitable electrolytes.

Our research team (Amanchukwu Lab) experimentally synthesized a novel electrolyte called tris(2-fluoroethyl) borate (TFEB), a fluorinated borate ester, and investigated for compatibility with LMBs through a series of experimental battery cycling tests. While our cycling tests validated the promising nature of the new electrolytes for LMBs, supporting our initial hypothesis, it presented a challenge: we could not explain our experimental results in terms of molecular behavior and interactions. Understanding these molecular details is not straightforward, as it involves comprehensively analyzing how the electrolyte’s molecules interact at the atomic level. This molecular insight is crucial because it allows us to predict and design the behavior of similar high-performance electrolytes in future experiments. In essence, gaining a clear molecular-level understanding is key to systematically developing electrolytes that can enhance the performance and safety of LMBs. To overcome this challenge, we turned towards cutting-edge computational methods, including quantum chemistry-based density functional theory (DFT) and ab-initio molecular dynamics (AIMD) simulations. These tools allowed us to delve deep into the molecular interactions within the battery, providing insights into the ion solvation (i.e., how lithium ions bond to different molecular components in electrolytes that ultimately decide their properties) environment and the solubility of lithium salts (this is crucial since electrolytes do not work unless salts dissolve in the organic liquids) in fluorinated borate esters.

The implications of this research are far-reaching. With improved solubility and stability offered by TFEB, LMBs can operate more efficiently and safely, paving the way for their use in a variety of applications, from consumer electronics to electric vehicles. Additionally, this study opens the door for future research where artificial intelligence (AI) and machine learning (ML) can play a pivotal role. The computational methods we used in our current work, while effective in predicting the properties of materials, face a significant limitation: they are computationally intensive. This makes them less feasible for exploring the vast chemical space of potential electrolyte candidates, which is astonishingly large, estimated to be in the order of 10ˆ60 possibilities! Here’s where AI algorithms can make a substantial impact. These advanced technologies have the potential to revolutionize how we approach the discovery of new electrolyte solvents. AI and ML are not just faster; they are capable of analyzing complex patterns and data relationships that are beyond human computational ability. This means they can predict, simulate, and optimize the properties of new electrolyte materials much more quickly and accurately than traditional methods. By leveraging AI, we can dramatically speed up the discovery process, potentially leading to breakthroughs in the development of more efficient and sustainable energy storage solutions. Our team is excited to be at the forefront of this innovation. We are actively exploring the use of AI and ML algorithms to tackle this grand challenge.

In summary, this research is not just about improving batteries; it’s about taking a significant step towards a more sustainable and technologically advanced future. With these advancements, the dream of long-lasting, safe, and efficient batteries is closer than ever.

This work was funded by the Eric and Wendy Schmidt AI in Science Postdoctoral Fellowship, a Program of Schmidt Futures.